Damage characterization of heat-treated titanium bio-alloy Ti-6Al-4V based on micromechanical modeling

Damage initiation and evolution in Ti-6Al-4V.

Damage initiation and evolution in Ti-6Al-4V.Abstract

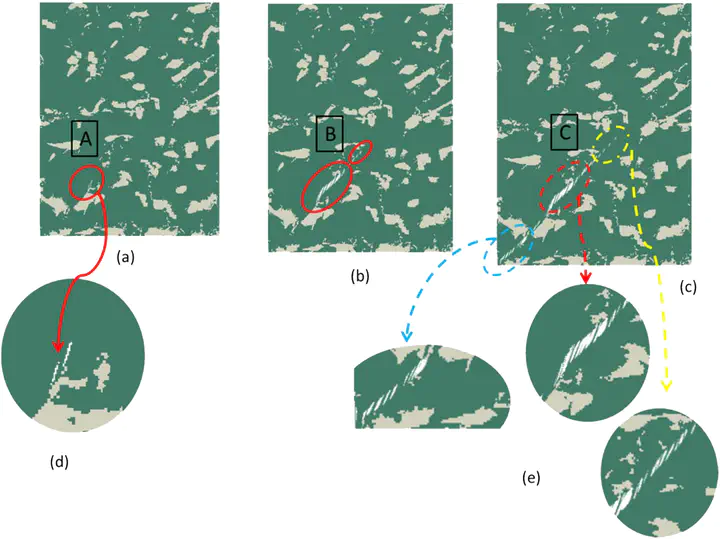

In this study, a micromechanical finite element model is proposed based on experimental data and the rule of the mixture (RoM) in order to predict the tensile behavior of mechanical properties of heat-treated dual-phase medical-grade titanium (Ti–6Al–4V). Tensile tests, micro-hardness measurements, and RoM were used to obtain flow curves for the α and β phases. Scanning electron microscopy (SEM) imaging was used to determine phase fractions and to create representative volume elements (RVEs). Furthermore, the Gurson-Tvergaard-Needleman (GTN) damage model was calibrated using the Taguchi design of experiment (DOE) method in order to predict damage in the microstructure and the results were compared to fracture surface obtained using fractography in order to investigate failure mechanisms. The final micromechanical model could accurately predict stress-strain curves and showed that void formation and coalescence is the primary mechanism of failure. Finally, analyses of the surfaces showed that a fully ductile fracture occurs at the failure point, which agrees with the results of the damage model. The results suggest that the proposed model can predict the failure of heat-treated Ti–6Al–4V bio-alloys.