Numerical Determination of Optimal Interphase Thickness in Dual-Phase Steels

Optimal thickness of gradient interphase with linear material properties in two DP steels.

Optimal thickness of gradient interphase with linear material properties in two DP steels.Abstract

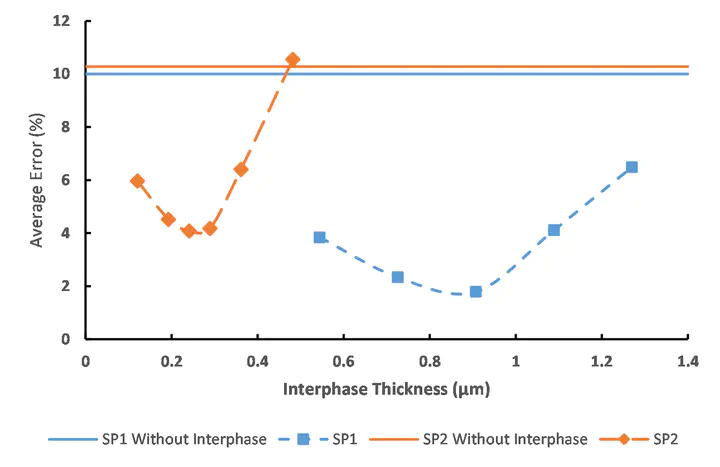

Micromechanical behavior of two dual-phase steels is investigated using experimental and numerical methods. Experimental data for 2 dual phase steel specimens (SP1 and SP2) is obtained from the literature and is used to create 2D representative volume elements (RVEs) based on the continuum mechanics framework. Interphase of the specimens is incorporated in the RVEs using digital image processing and flow curves are modeled based on a linear interpolation between flow curves of the two phase. The effect of interphase thickness is investigated to determine an optimal thickness of the interphase region for each steel specimen, based on the average error between experimental and numerical stress-strain curves. It was concluded that for SP1 and SP2, models with interphase thickness of less than 1.4 $\mu$m and 0.45 $\mu$m can predict stress-strain response better than the model without interphase. Also, optimal interphase thickness values of 0.90 $\mu$m and 0.24 $\mu$m have been obtained for the two specimens respectively. Also, it was demonstrated that failure initiates at the interphase and then propagates to the ferrite phase.